A long stemmed goblet with captive ring feature. The captive ring isn’t a difficult feature, but it does take patience to create.

The wood is spalted beech, spalted meaning the wood has been infected with a fungus. While this gives the wood the beautiful black lines and bi-colour effect, it also makes the wood a bit more difficult to work. Spalting can mean the wood is something less stable, with parts of it having a “spongy” feel. In addition, this particular piece also had a tunnel carved through it nearly in to the centre by a wood worm, which wasn’t revealed until I began to turn the stem. Parts of the tunnel can be seen in the steam and captive ring. A few millimeters more and the tunnel might have ruined the goblet.

Finished in sanding sealer and wood wax.

Above: the wood worm tunnel exposed on the captive ring.

Here are some pictures as a work in progress.

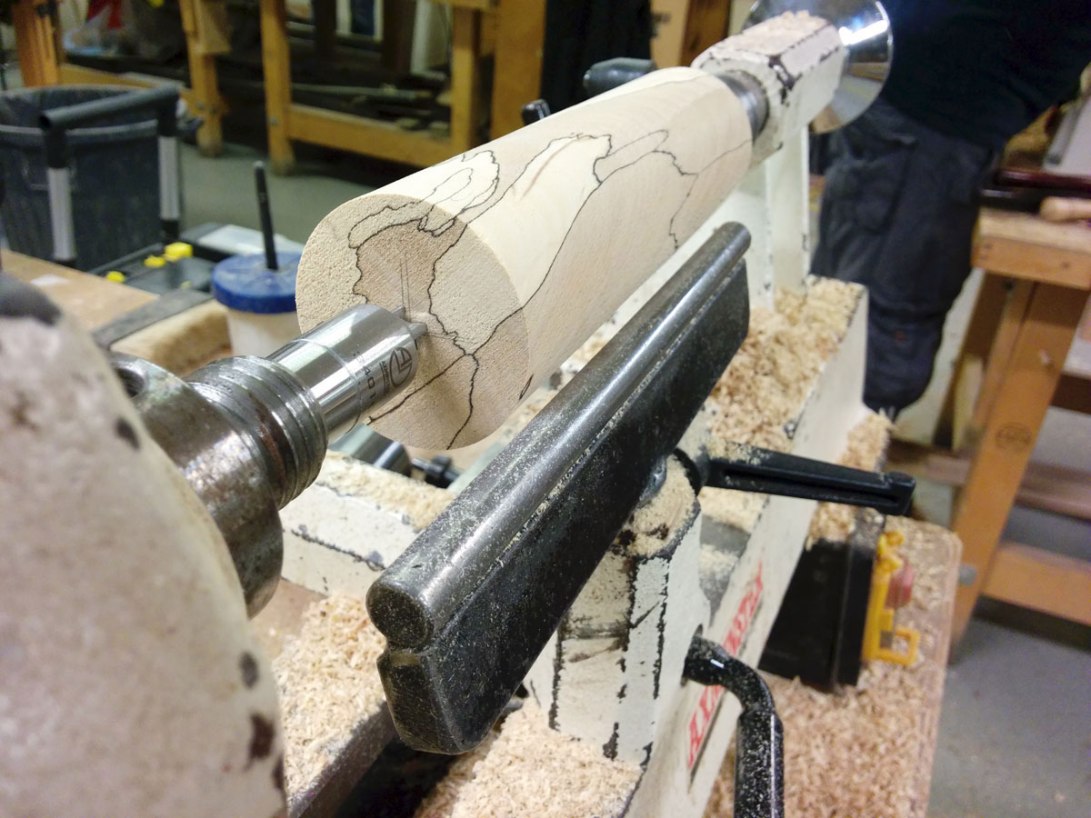

The wood is loaded on the lathe and roughed down to a cylinder. From here on out, it will be worked from the far end. I will work a section to finish, sanding and finishing, then move to the next section. This is because the wood is most stable at the spindle head end. The inside of the cup will be the first part worked. A tenon will be created so the blank can be held in a chuck by one end, leaving the other end open for working. Once that is done, the blank will mounted between spindles again, but with a cushion on the rear spindle to project the inside of the cup.

Beginning to work the captive ring.

After the captive ring is separated and sanded, it is taped to the finished area to keep it out of the way. The rest of the stem and then the foot is now worked. Here the foot is nearly done and I have made a groove showing where the goblet will be parted off.